Published on Apr 02, 2024

The development of the nuclear power industry has been nearly stagnant in the past few decades. In fact there have been no new nuclear power plant construction in the United States since the late 1970s. What many thought was a promising technology during the "Cold War" days of this nation; they now frown upon, despite the fact that nuclear power currently provides the world with 17% of its energy needs.

Nuclear technology's lack of popularity is not difficult to understand since the fear of it has been promoted by the entertainment industry, news media, and extremists. There is public fear because movies portray radiation as the cause of every biological mutation and now; terrorist threats against nuclear installations have been hypothesized. Also, the lack of understanding of nuclear science has kept news media and extremists on the offensive. The accidents at Three Mile Island (TMI) and Chernobyl were real and their effects were dangerous and, in the latter case, lethal. However, many prefer to give up the technology rather than learn from these mistakes.

Recently, there has been a resurgence of interest in nuclear power development by several governments, despite the resistance. The value of nuclear power as an alternative fuel source is still present and public fears have only served to make the process of obtaining approval more difficult. This resurgence is due to the real threat that global warming, caused by the burning of fossil fuels, is destroying the environment. Moreover, these limited resources are quickly being depleted because of their increased usage from a growing population.

The estimation is that developing countries will expand their energy consumption to 3.9 times that of today by the mid-21st century and global consumption is expected to grow by 2.2 times. Development has been slow since deregulation of the power industry has forced companies to look for short term return, inexpensive solutions to our energy needs rather than investment in long term return, expensive solutions. Short-term solutions, such as the burning of natural gas in combined cycle gas turbines (CCGT), have been the most cost effective but remain resource limited. Therefore, a few companies and universities, subsidized by governments, are examining new ways to provide nuclear power.

An acceptable nuclear power solution for energy producers and consumers would depend upon safety and cost effectiveness. Many solutions have been proposed including the retrofit of the current light water reactors (LWR). At present, it seems the most popular solution is a High Temperature Gas Cooled Reactor (HTGR) called the Pebble Bed Modular Reactor (PBMR).

The history of gas-cooled reactors (GCR) began in November of 1943 with the graphite-moderated, air-cooled, 3.5-MW, X-10 reactor in Oak Ridge, Tennessee. Gas-cooled reactors use graphite as a moderator and a circulation of gas as a coolant. A moderator like graphite is used to slow the prompt neutrons created from the reaction such that a nuclear reaction can be sustained. Reactors used commercially in the United States are generally LWRs, which use light water as a moderator and coolant.

Development of the more advanced HTGRs began in the 1950s to improve upon the performance of the GCRs. HTGRs use helium as a gas coolant to increase operating temperatures. Initial HTGRs were the Dragon reactor in the U.K., developed in 1959 and almost simultaneously, the Arbeitsgemeinshaft Versuchsreaktor (AVR) reactor in Germany.

Dr Rudolf Schulten (considered "father" of the pebble bed concept) decided to do something different for the AVR reactor. His idea was to compact silicon carbide coated uranium granules into hard billiard-ball-like graphite spheres (pebbles) and use them as fuel for the helium cooled reactor.

The first HTGR prototype in the United States was the Peach Bottom Unit 1 in the late 1960s. Following the success of these reactors included construction of the Fort S. Vrain (FSV) in Colorado and the Thorium High Temperature Reactor (THTR-300) in Germany. These reactors used primary systems enclosed in prestressed concrete reactor vessels rather than steel vessels of previous designs. The FSV incorporated ceramic-coated fuel particles imbedded within rods placed in large hexagonal shaped graphite elements and the THTR-300 used spherical fuel elements (pebble bed). These test reactors provided valuable information for future design.

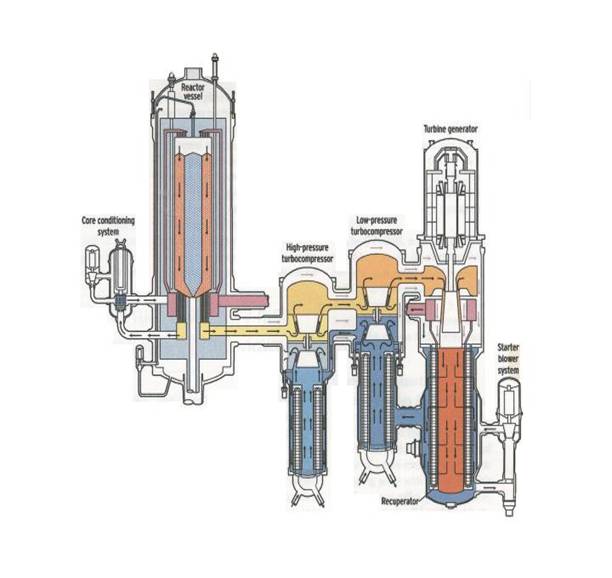

The commercial effort of the PBMR is the most publicized and information about it is readily available. A description of it would cover most aspects of the modern HTGR pebble bed reactors. Figure 2 shows a cross-section of the PBMR reactor and energy convertor. Therefore, the PBMR can be separated in two distinct parts. The first part is the heat source, labeled "reactor vessel", and the second part contain the power conversion units, labeled "high-pressure turbo compressor", "low-pressure turbo compressor", and "turbine generator".

The nuclear reaction takes place within the "reactor vessel" which is a vertical steel pressure enclosure that is 6 meters in diameter and 20 meters high. The enclosure is lined with a layer of graphite bricks which serve as an outer reflector for the neutrons generated by the reaction and a passive heat transfer mechanism. This lining is drilled with vertical holes for insertion of the control rods. Illustrated by the red and blue-pebbled granules, the inner reactor core portion consists of two zones and is 3.7 meters in diameter and 9.0 meters high. The blue, or inner zone, contains approximately 185,000 graphite spheres and the red, outer zone, contains approximately 370,000 fuel spheres.

The graphite spheres serve as a moderator for the nuclear reaction. This moderator slows the prompt neutrons created from the reaction such that a nuclear reaction can be sustained. As the arrows indicate, helium flows through the fuel pebble bed and is heated to provide working fluid for the generator. The helium also naturally serves as a coolant for the reactor as well; much like water does for today's LWRs

The remaining components of the reactor can best be described using the complete schematic diagram shown in Figure 3 .As it illustrates, helium enters the reactor at 500 degrees Celsius and at a pressure of about 8.4 MPa. It leaves the reactor at about 900 degrees Celsius and drives the high-pressure turbine. The high-pressure turbine will drive the return high-pressure compressor. After the high-pressure turbine, the helium flows through the low-pressure turbine that drives the low-pressure compressor. While still hot, the helium leaves the low-pressure turbine and drives the power turbine to produce the electricity through the generator. The helium leaves the power turbine and is cooled in the recuperator.

Return helium is then compressed back to a pressure of 8.5 MPa while it returns through the pre-cooler, low-pressure compressor, inter-cooler, and high-pressure compressor. The coolers increase the efficiency of the compressors since they increase the density of the helium. The helium has also been cooled back down to 500 degrees Celsius and the cycle repeats itself as it travels back to the reactor. This process is called the Brayton (gas turbine) Cycle.

The advantage of this process is its high efficiency of thermal energy transfer to electrical energy. As mentioned, the efficiencies of today's LWRs are approximately 30% where the PBMR yields approximately 44%.

| Are you interested in this topic.Then mail to us immediately to get the full report.

email :- contactv2@gmail.com |